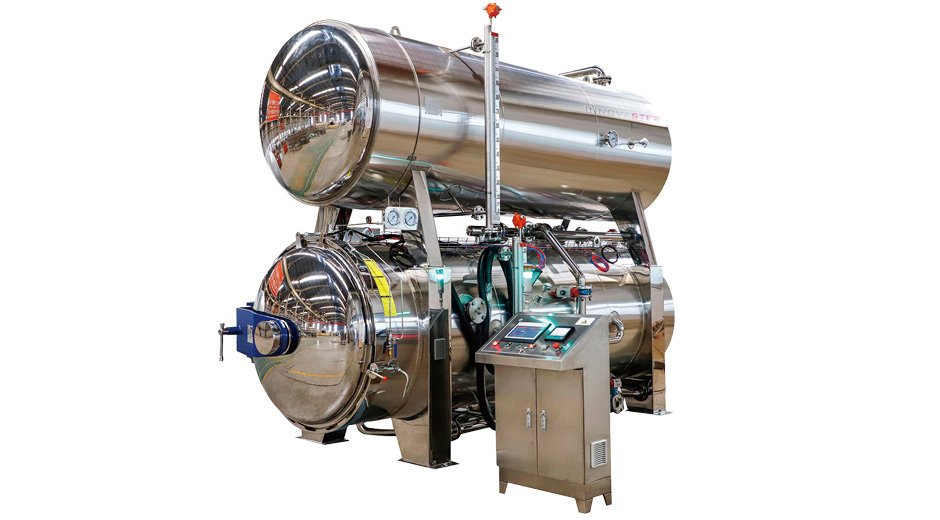

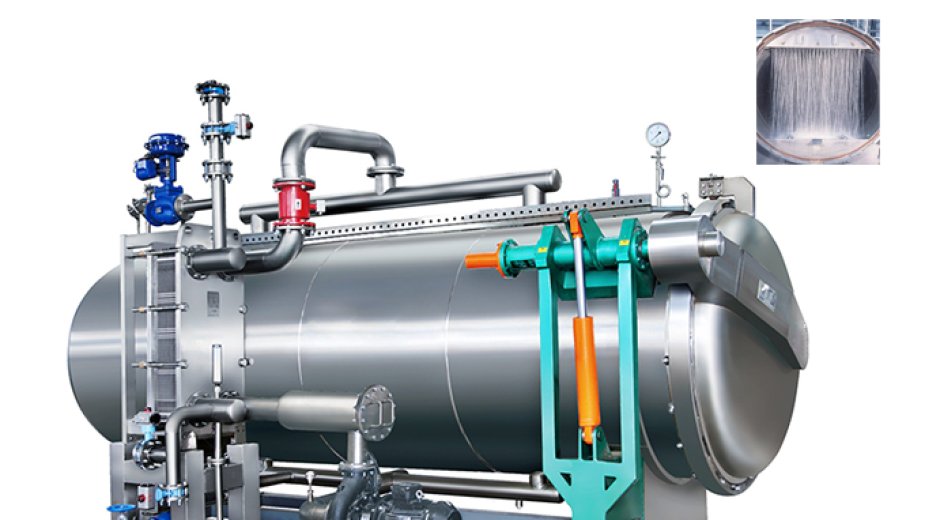

Innovaster Water Spray process is an overpressure process, it’s different from Saturated Steam process in that air can be introduced into the vessel during sterilization. Preheat Tank is an OPTIONAL to preheat the process water while operator is entering the process recipe for hot filling products. During process, water is sprayed over the containers from different angles, steam can go through the other loop of the heat exchanger to heat the process water or directly injected into vessel. Water Spray process can be used for various packages thermal processing, excellent temperature distribution and efficient heat transfer since Innovaster selects all top-class brands components to provide the high-quality retorts and service to our customers worldwide and because of our know-how. HMI controls provide a user-friendly interface to retort control.

-

Retorts/Autoclaves

Water Spray RetortsRead more

Water Spray RetortsRead more Water Immersion RetortsRead more

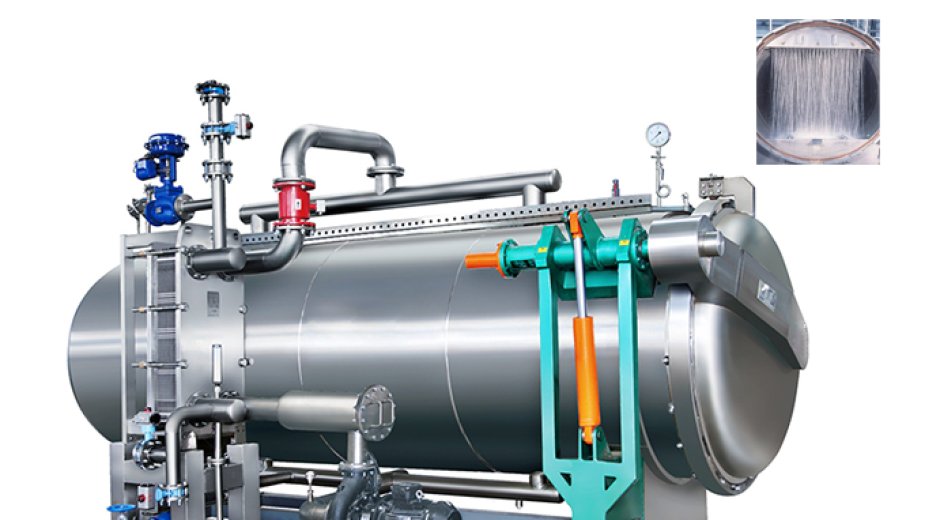

Water Immersion RetortsRead moreSuperheated water contained in the storage vessel allows for a short come-up time. Hot water envelops the containers thus even temperature penetration into the products from all sides. Optimized water circulation system guarantees homogenous temperature distribution. Less stress on the containers achieved by the buoyancy effect from immersing the load in water, such as semi-rigid trays, pouches etc. Rotary agitation function is available, perfect for products of high viscosity, such as condensed milk, flavored milk in plastic bottles, canned corn which need End-over-end rotation for forced convection or prevent burning on the container walls during heating.

Steam RetortsRead more

Steam RetortsRead moreInnovaster Direct Steam Retort will be used to process rigid containers such as cans. retort chamber should be saturated at the beginning for air is considered an insulating medium and all air will be evacuated from the retort by flooding the vessel with steam and allowing the air to escape through vent valves. There is no overpressure during the sterilization phases of this process,and air-overpressure will be applied during the cooling steps to prevent container deformation.

Steam-Air RetortsRead more

Steam-Air RetortsRead moreSteam Air Retort is fitted with Fan Motor and Air Tunnel compared with traditional steam retort. The circulation of steam is forced by a powerful fan inside the retort which makes travelling steam horizontally and evenly to guarantee a perfect temperature homogeneity and temperature distribution.

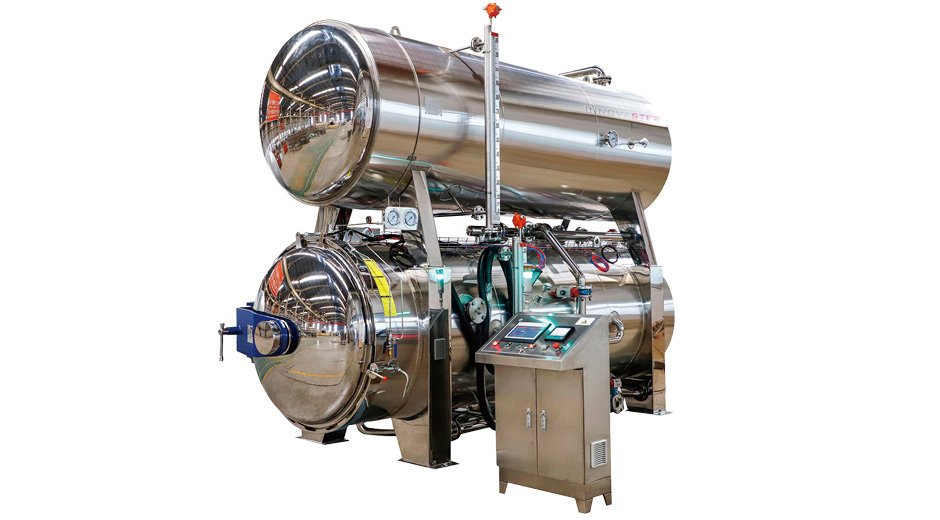

Rotary RetortsRead more

Rotary RetortsRead moreRotary retorts are used to process the food contents in order to accelerate the heat transfer inside the container, with a movement of food inside to provides even better product quality and process efficiency. The baskets or stacks of trays are clamped individually to ensure that the load is well supported with no damage to the containers or baskets and trays. The clamping mechanisms as well as other moving parts like rotor shaft or supporting rollers (trunnions) are designed for heavy duty and long life.

Water Cascade RetortsRead more

Water Cascade RetortsRead moreWater cascade retort provides air overpressure processing. Good temperature distribution and efficient heat transfer. Excellent pressure control. Insignaficate maintenance cost

Pilot RetortsRead more

Pilot RetortsRead morePilot retorts are the best option for R&D purposes with small output,especially new foods and new packs in formulating scheduled process of new products, simulating sterilization environment in real production, measuring F0 value for mass production etc. Sometimes, our customers use the pilot retorts for the improvement of existing recipes or renewed product formulations to produce small quantities for market testing their new launches. Our Pilot retort capabilities include saturated steam, steam-air, water spray, water cascade and water immersion, rotary end-over-end.

Retort AccessoriesRead more

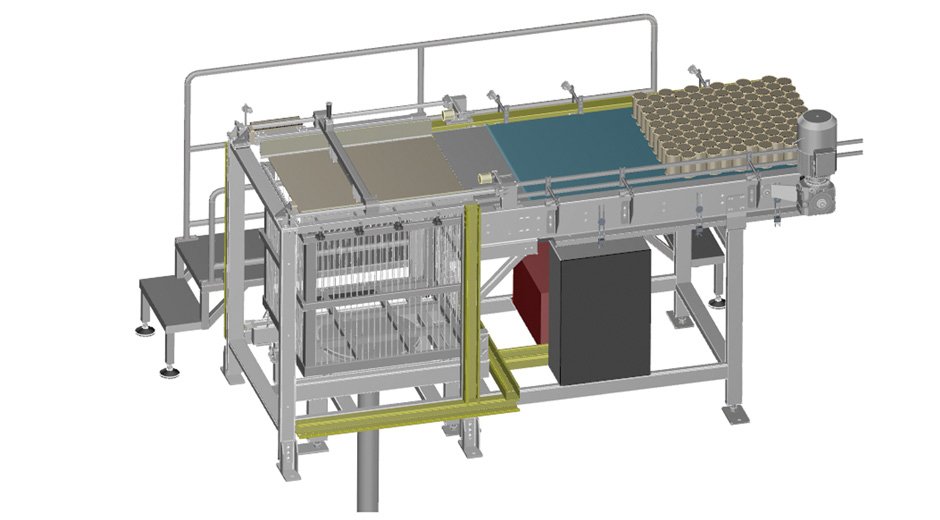

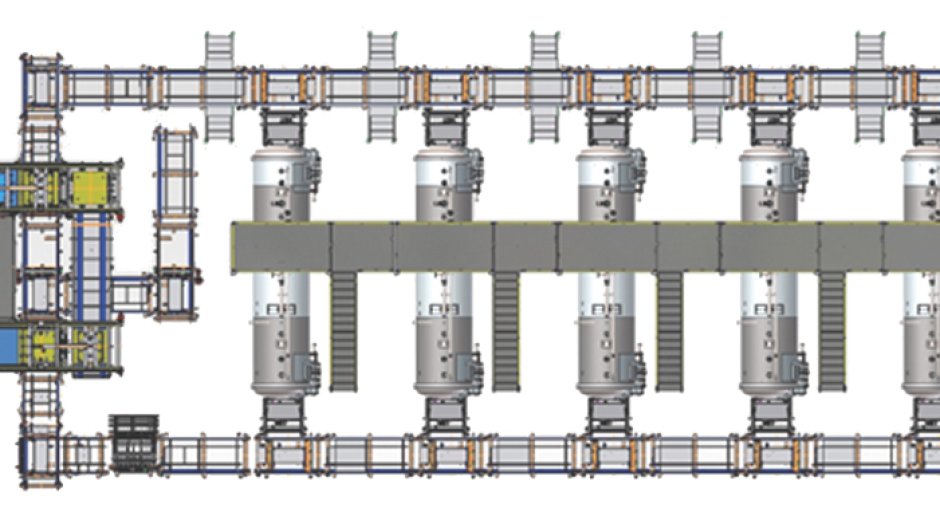

Retort AccessoriesRead moreOur retort solutions include different design of retort baskets, trays and trolleys for manual handling, semi-automatic basket and loading and unloading machines, up to fully automatic handling systems (ABRS).

-

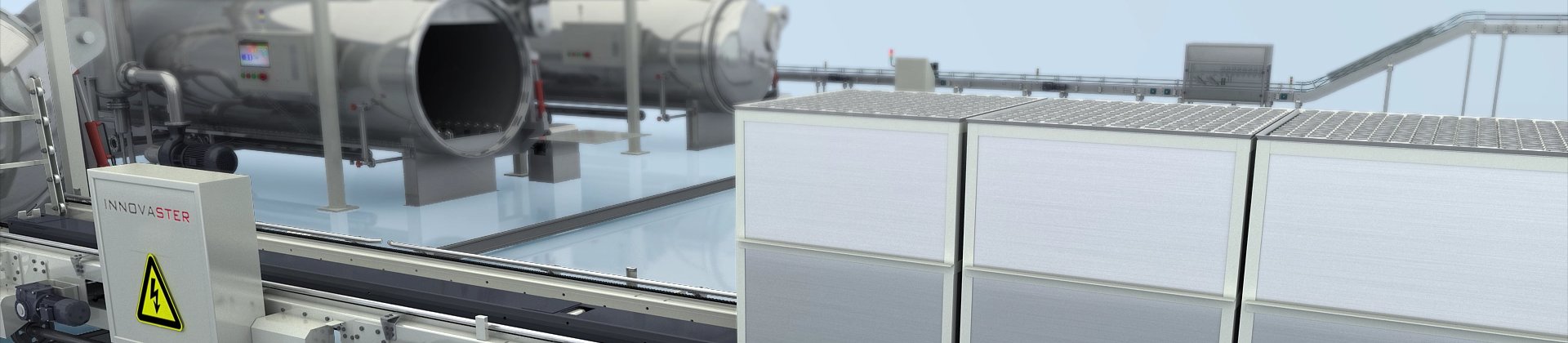

Shuttle And Loading/Unloading Machine

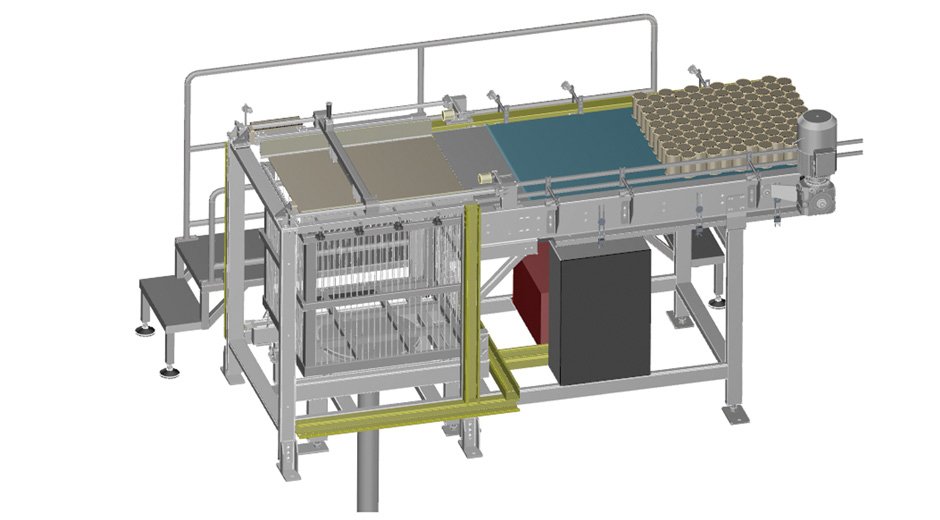

Semi Automatic Loader UnloaderRead more

Semi Automatic Loader UnloaderRead moreSemi-Auto Basket Loaders and Unloaders provide canned food manufacturers with consistent automated throughput at the low capital outlay.

Retort ShuttleRead more

Retort ShuttleRead moreShuttle is a basket travel system under control of the system PLC that satisfy a batch-at-a-time collection of product baskets deliver to the retorts. The shuttle is integrated with raw product conveyors and processed product conveyors. Baskets that are loaded are staged on the shuttle until a retort load of baskets has been accumulated.

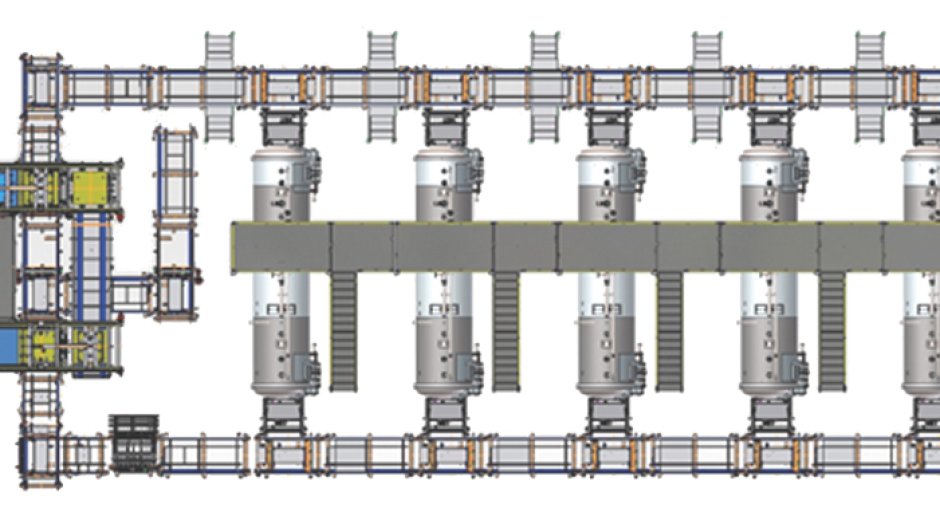

Full Automatic Loader UnloaderRead more

Full Automatic Loader UnloaderRead moreLoaders and unloaders can be fully automated systems for high-speed requirements with integration of all hardware designed for transportation of baskets from loader station to sterilization retorts and from there on to an unload station and packaging area. The global handling system can be monitored by a basket/pallet tracking system.

-

Vacuum Fryer

Vacuum Fryer MachineRead more

Vacuum Fryer MachineRead morelnnovaster Vacuum Fryer consists in the main of the fryer proper, an oil filter, oil heating element, and a vacuum unit. The system is a revolutionary concept of food preparation, with dehydration taking place while frying the food in the high-vacuum system at a low temperature.